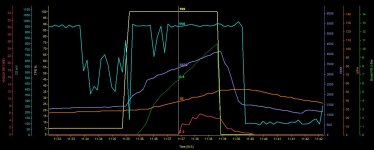

I believe you’re correct. I remember something too about preload and a side view pic of the eyelet WAY back in the day. The way I did it yesterday I loosened the jam nut, made It so the left side of the eyelet touched the left side of the stud (holding the wastegate arm closed), turned the eyelet half a turn for some tension, then pulled it over the stud n clipped it. It’s about 3 threads away from the previous setting. Maybe too conservative, but it was so spiky I have to try something different while I had it all open.

The way I checked 20+ years ago, I didn’t know wtf I was doing lol, I bought a mity-vac and pumped the actuator and it moved... looked good to me. I showed my BMW mechanic friend, looked good to him.